The hydrogen market is currently undergoing a transition as fossil fuel-based hydrogen is projected to decline, while green hydrogen produced via electrolysis is poised to grow quickly. However, the proliferation of green hydrogen projects is likely to impact the water cycle as many projects are being planned in water-stressed regions.

Water has always been fundamentally intertwined with energy – water is a key part of energy production and energy is a key part of water and wastewater systems. This is widely known as the water-energy nexus and has been driving conversations on the interdependency and joint challenges/opportunities of the two sectors. This same relationship exists when you think about the hydrogen economy, so it is critical for stakeholders to understand how the scaling of hydrogen production (particularly green hydrogen) will impact water resources and systems.

Water Requirements

The current dominant method of hydrogen production is steam methane reforming (SMR), which uses high temperature steam to produce hydrogen from methane. This hydrogen is classified as “grey” or “blue” (if combined with carbon capture & sequestration). SMR requires about 4.5kg of water for every kg of hydrogen produced.

An alternative method of hydrogen production which is growing quickly is electrolysis, which uses electricity to split water into hydrogen and oxygen. On a chemical level, about 9kg of water are required to produce 1kg of hydrogen. This is twice as much water that is required for SMR. However, this process water is a small percentage of overall water needs. Both electrolysis and SMR require a significant amount of water for cooling – some of which is discharged back to the environment, and some of which is lost to evaporation.

Total water requirements can depend on a number of factors, including water quality and treatment method used. Much is unknown about the water impacts and estimates can vary widely – we have seen estimates anywhere from 9-24kg (Bluefield) to 1210kg (GWI estimate using desalination). The typical range appears to be about 60-95kg of water needed per 1kg of hydrogen, with the majority being used for cooling.

Estimated Water Demand

Water Process for Electrolysis

Taking a closer look at the electrolysis process reveals that the water system is a critical piece. An electrolysis plant is typically connected to a water source that supplies both the feedstock and cooling water. That source can be either municipal potable water or an alternative source (freshwater, brackish water or sea water). There is opportunity for many of these projects to be co-located with other industrial users of water or even next to wastewater treatment plants so that recycled water can be used (see Cepsa project example).

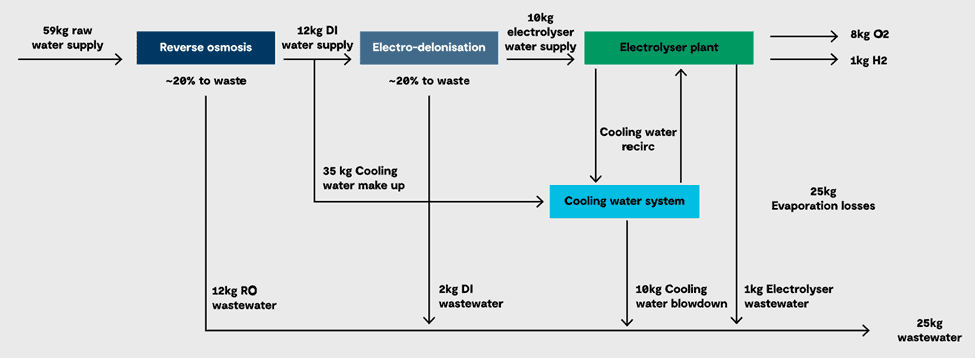

The process water for the electrolyzer must be ultrapure, and therefore, goes through both reverse osmosis (RO) and deionization in order to meet the quality requirements. A significant portion (20% or more) is rejected as wastewater during the treatment process. A portion of the RO treated water is diverted to the cooling water system, which is recirculated and eventually discharged back to the environment. The graphic below provides additional details on the water process.

Planned Projects

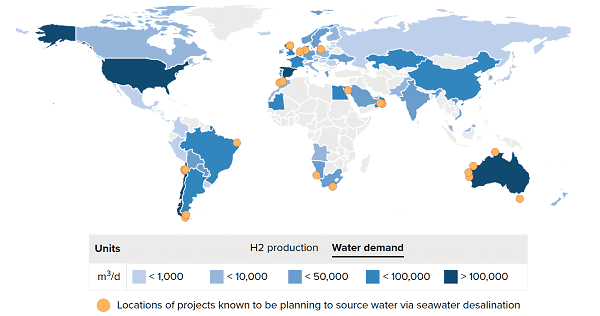

Bluefield Research estimates that 85% of planned hydrogen projects are expected to be in water stressed areas, but the majority of these have not disclosed the water source they will use.

Of the projects that have disclosed, ~40% are planning to use desalinated seawater. Desalination is one way of reducing the stress to local water sources that can be utilized by projects in coastal areas. However, it can be expensive compared to other water sources, contributing to higher green hydrogen prices (which are already ~3x higher than grey and blue hydrogen).

Anticipated Water Demand for Green Hydrogen Projects by 2030

Conclusion

Clearly, more work and transparency are required to understand the water needs of green hydrogen and how that will impact local water sources. Already, there are some examples of projects being cancelled due to lack of water. The conversation around green hydrogen is a good reminder that lower emissions does not necessarily mean lower water consumption, and solutions must be viewed holistically to understand the overall climate impact.

Xylem is highlighting this important issue through our Global Student Innovation Challenge. Students will have the opportunity to learn about the water impact of green hydrogen and evaluate the repercussions on a country, region and global level. After the challenge closes on April 22, we will come back to share some of the innovative ideas the students proposed!

Sources:

- https://www.energy.gov/eere/fuelcells/hydrogen-production-natural-gas-reforming

- https://www.ghd.com/en/perspectives/water-for-hydrogen.aspx

- Bluefield – Hydrogen to Spark Water-Focused Strategies (2022)

- GWI – Hydrogen powers up new markets for the water sector (2021)

- https://www.rechargenews.com/energy-transition/vast-majority-of-green-hydrogen-projects-may-require-water-desalination-potentially-driving-up-costs/2-1-1070183

- https://www.gwiwaterdata.com/industries/green-hydrogen#card-339028