Deploying Advanced Metering Infrastructure (AMI) is a challenge. Many factors go into standing up an AMI system, from installing meters to deploying collectors to integrating back-end systems. Before the first meter is placed in a socket, utilities have the challenging task of deciphering the differences between various AMI architectures. Often, network infrastructure maintenance costs are not taken into account when deciding on an AMI solution.

The two most common AMI network architectures are mesh and point-to-multipoint. In a mesh network, smart meters receive, store, and transmit signals in many different directions as a primary part of its communications architecture. Endpoints send transmissions on unlicensed radio frequencies, which hop from meter to meter, relaying the information until it ultimately reaches a collector and/or a router.

In a licensed point-to-multipoint network, smart meters transmit directly to collectors without relying on other meters to form the system. In general, these collectors, or base stations, are placed on hardened assets such as water towers, utility-owned substations, or other third-party structures.

Both network architectures require some level of upkeep. However, there are three overlooked concepts worth investigation when exploring network infrastructure maintenance costs:

- Total number of field devices deployed

- Replacement of consumable parts

- Network performance management

The concepts above are often overlooked or viewed as negligible costs. However, in actuality, that is not the case.

Total Number of Field Devices

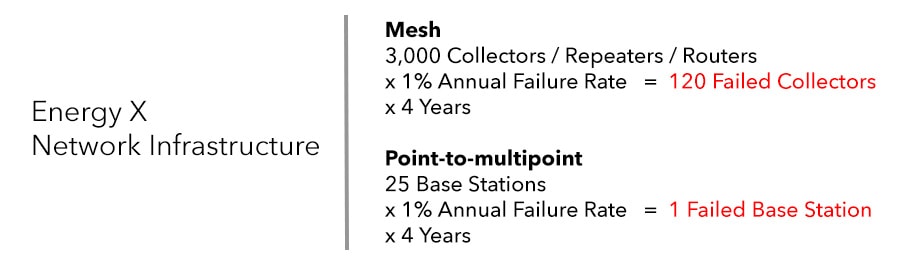

In manufacturing, there is the phrase “acceptable failure rate.” This is the frequency of how often a component fails over a period of time. Depending on the industry, this can range from 0.5% to 3%. It’s also important to remember that failure rates are not linear. As components age, it becomes more likely to experience failure.

It stands to reason that as more devices are in the field, the greater the probability that there will be a failure.

To illustrate this point, let’s examine the actual network infrastructure requirements for a mid-sized electric utility with 100,000+ endpoints. For anonymity purposes, the utility will be referred to as Energy X. In the following example, we’ll operate under the assumption that there is an average failure rate of 1% annually over four years.

The differences can be staggering. Where it becomes more difficult is to place a dollar amount on the cost of failure. Yes, it’s easy to place an average cost on a truck roll, but there are always hidden expenses involved as well. How does a network failure affect daily operations? Is the maintenance headache taking time away from a different project? Are you needing to change internal processes to account for meters that are having trouble communicating?

As you can see, the challenges mount.

Replacement of Consumable Parts

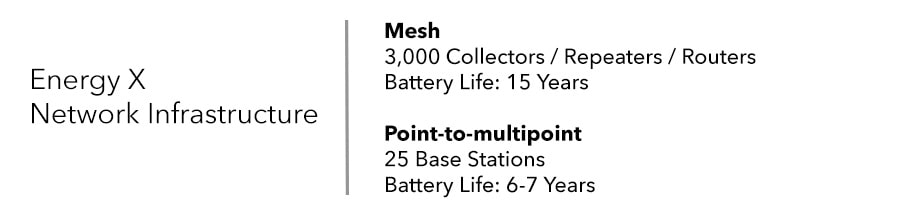

Individual components tend to degrade over time, and the most common is probably the battery. Whether it’s a car, cell phone, or network collector, batteries slowly deteriorate over time, and replacement is inevitable. Battery lifespan varies depending upon the type of battery, environmental factors, and more. In the example below, we looked at published specs to give standard battery life.

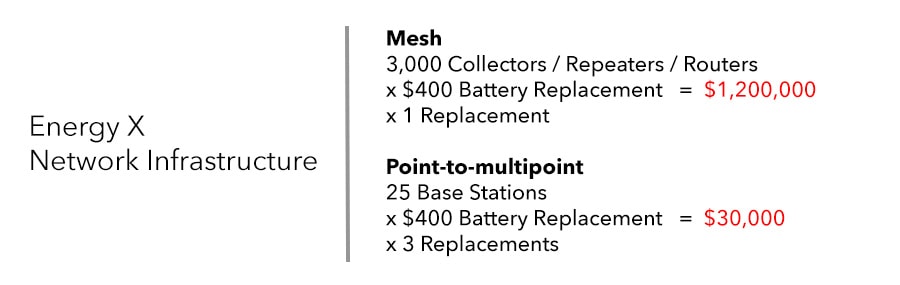

Under this example and assuming that your AMI network has a 20-year life cycle, you’ll need to replace batteries at least once for a mesh network and two or three times for a point-to-multipoint system. We’ll assign $400 per network point to perform the maintenance and battery replacement for these purposes.

One challenge, when comparing the two systems, is that even replacing a battery is different. With a mesh network, the collectors/routers are usually placed at the top of electric power poles along roadways, requiring a bucket truck to service. Conversely, base station cabinets on point-to-multipoint networks are typically installed at a serviceable height in a secure area. This is a significant difference that directly affects how the utility services collectors. Minor operational differences such as this add up over the life of the network.

As you can see, battery replacement costs alone are a significant expense over a system’s life.

Network Performance Management

Another oft-overlooked AMI maintenance challenge is managing the network’s performance. To better understand this, we’ll need to explore the differences between how mesh and point-to-multipoint systems transmit messages.

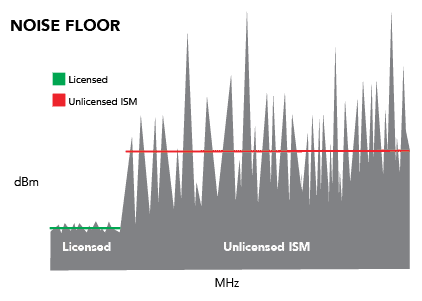

With a mesh network, transmissions are made over an unlicensed or shared spectrum known as the ISM band. This band is intended for low-data rate communications and extends from 902 to 928 MHz. When a utility first launches a mesh system, it is carefully calibrated with considerations for the current noise floor level. The noise floor is made up of unwanted signals from different devices sharing the same frequency band, such as microwaves, garage door openers, or baby monitors. The challenge for utilities is that the noise floor is continually changing and becoming more crowded. For example, just over the past few years, smart devices such as the Amazon Echo and Ring doorbell have exploded in popularity—adding to the congestion.

This means that the network designs originally proposed often need significant adjustments to account for changes in the noise floor. When the noise floor rises, the range between meters typically gets shorter. Utilities install additional collectors to reach “islanded” pockets of meters whose signals aren’t being read to address this. Sometimes the utility can get away with moving collectors around, but it is tough to predict where they will be needed as one can imagine. It can become a full-time job for utilities to manage these unread meters as the noise floor changes over time.

Licensed point-to-multipoint networks operate on protected, unshared spectrum assigned by the federal government to a single provider. This helps maintain predictable, interference-free communication between meters and collectors. Since the noise floor does not vary significantly over time, utilities can accurately determine where to install collectors and maintain the system’s initial performance. In the rare case that unwanted radio frequency noise affects operations, utilities have the peace-of-mind of knowing that they can lean on the FCC for federal protection. With point-to-multipoint systems, the initial installation of collectors will suffice, and there is typically no need to add more in the future to mitigate interference. Radiofrequency management, therefore, is a negligible expense with licensed frequency point-to-multipoint networks.

Conclusion

Network infrastructure maintenance is often an overlooked but vitally important part of any AMI solution. As the number of deployed assets increase, the cost of care goes up as well. Utilities must consider an acceptable failure rate for field-deployed assets, the vendor-provided regular maintenance schedule, and radio-frequency management to get a complete picture of annual infrastructure maintenance costs.

It appears the cost shown for mash battery replacement is incorrect. $1.2M vs $2.4M as shown.

You are 100% correct—good catch. I made the change in the graphic to reflect your comment. Thanks for taking the time to write a note.